How Milk Collection Software Revolutionizes Business Efficiency and Profitability

The dairy industry faces unprecedented challenges in today’s competitive marketplace. Rising operational costs, stringent quality standards, complex supply chain management, and increasing consumer demands for transparency have pushed traditional dairy operations to their limits. For dairy business owners seeking sustainable growth and improved profitability, the solution lies in embracing technology that streamlines operations from farm gate to consumer.

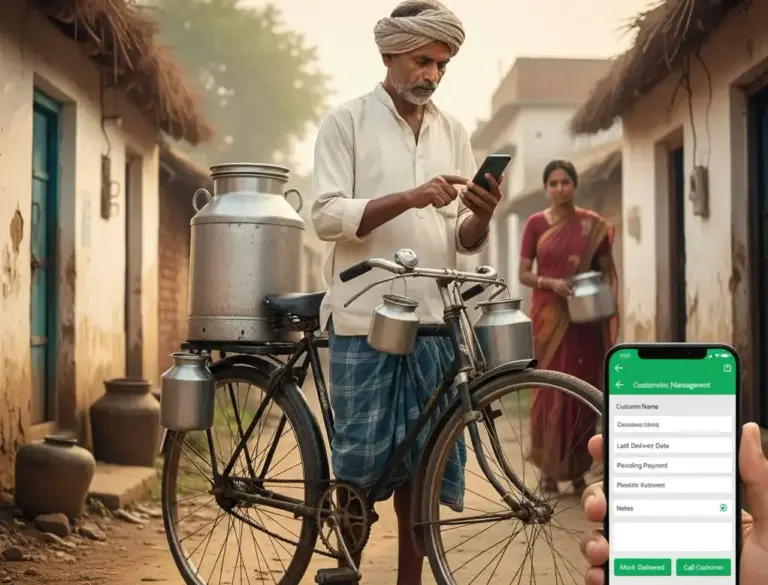

Milk collection software has emerged as a game-changing solution that transforms how dairy businesses manage their most critical processes. This specialized technology goes beyond simple record-keeping to create an integrated ecosystem that optimizes every aspect of milk collection, processing, and distribution while ensuring compliance with industry regulations.

The Hidden Costs of Manual Milk Collection Management

Traditional milk collection methods burden dairy operations with inefficiencies that directly impact the bottom line. Manual data entry consumes valuable time and introduces human errors that can cost thousands in product losses and regulatory penalties. Without real-time visibility into collection routes, milk quality parameters, and supplier performance, dairy businesses operate blindly, making decisions based on outdated information.

Consider the ripple effects of a single quality control failure: contaminated milk batches require disposal, supplier relationships suffer, production schedules halt, and customer trust erodes. The financial impact extends beyond immediate losses to include regulatory fines, increased insurance premiums, and long-term reputation damage that affects market positioning.

Manual tracking systems also create bottlenecks in supplier payments, leading to cash flow issues for farmers and strained relationships with collection partners. These operational friction points accumulate over time, creating a competitive disadvantage that becomes increasingly difficult to overcome as the industry evolves toward digitization.

Revolutionary Features That Drive Business Growth

Modern milk collection software integrates seamlessly with existing dairy operations while introducing powerful capabilities that transform business performance. Real-time route optimization reduces fuel costs by up to 20% while ensuring optimal collection schedules that maximize milk freshness and minimize spoilage.

Automated quality testing integration captures critical parameters like fat content, protein levels, and bacterial counts directly from collection points. This immediate data availability enables instant quality decisions, preventing contaminated milk from entering the processing stream and protecting brand reputation. The software automatically generates certificates of analysis and compliance documentation, eliminating manual paperwork and reducing administrative overhead.

Supplier management becomes effortless with automated payment calculations based on quality parameters and volume metrics. Transparent reporting builds trust with farmers while providing detailed analytics that identify top-performing suppliers and highlight areas for improvement. Digital contracts and compliance tracking ensure all suppliers meet regulatory requirements without manual oversight.

Temperature monitoring throughout the cold chain prevents quality degradation and ensures product safety from collection to processing. Instant alerts notify managers of any deviations, enabling immediate corrective action that prevents product losses and maintains quality standards.

Maximizing Revenue Through Data-Driven Decisions

Milk collection software transforms raw operational data into actionable business intelligence that drives revenue growth. Detailed analytics reveal patterns in supplier performance, seasonal variations, and quality trends that inform strategic decisions about pricing, sourcing, and production planning.

Predictive analytics capabilities forecast supply volumes and quality parameters, enabling proactive production scheduling that maximizes plant utilization and minimizes waste. This forward-looking approach reduces inventory carrying costs while ensuring adequate supply for market demands.

Quality premium programs become manageable through automated grading systems that reward suppliers for superior milk quality. These incentive structures encourage better farming practices while securing higher-quality raw materials that command premium prices in the marketplace. The software tracks and documents these programs automatically, eliminating disputes and building stronger supplier relationships.

Route optimization algorithms continuously improve collection efficiency, reducing operational costs that directly translate to improved margins. Fuel savings, reduced vehicle wear, and optimized driver schedules create cumulative cost reductions that significantly impact profitability over time.

Ensuring Compliance and Quality Standards

Regulatory compliance represents one of the most critical aspects of dairy operations, with violations carrying severe financial and operational consequences. Milk collection software provides comprehensive compliance management that automatically tracks all regulatory requirements and generates necessary documentation for audits and inspections.

Traceability systems create complete audit trails from individual farms through processing and distribution. This capability proves invaluable during food safety incidents, enabling rapid identification of affected products and minimizing recall scope. The detailed documentation also supports organic and specialty certifications that command premium prices.

Automated hazard analysis and critical control point (HACCP) monitoring ensures continuous compliance with food safety regulations. The software tracks critical control points, documents corrective actions, and maintains verification records that satisfy regulatory requirements while protecting against liability.

Quality assurance protocols become standardized across all collection points, ensuring consistent milk quality that meets processing requirements and customer expectations. Automated rejection protocols prevent substandard milk from entering the system while providing clear documentation for supplier feedback and improvement programs.

Streamlining Operations for Maximum Efficiency

Integration capabilities allow milk collection software to connect with existing enterprise resource planning (ERP) systems, accounting software, and processing equipment. This seamless data flow eliminates duplicate data entry while ensuring information consistency across all business systems.

Mobile applications enable field personnel to access real-time information, update collection data, and communicate with management from any location. This connectivity eliminates communication delays and ensures accurate, timely data collection that supports informed decision-making.

Inventory management features track milk storage levels, aging, and allocation across different product lines. This visibility prevents spoilage while optimizing inventory turns and ensuring adequate supply for production requirements.

Automated reporting systems generate customized reports for different stakeholders, from operational dashboards for plant managers to financial summaries for executives. These reports provide the visibility needed to monitor performance, identify opportunities, and make data-driven improvements.

Building Stronger Supplier Relationships

Milk collection software transforms supplier relationships through transparency, fair payment systems, and collaborative quality improvement programs. Suppliers gain access to their performance data, quality metrics, and payment calculations, building trust and encouraging participation in improvement initiatives.

Communication tools facilitate direct interaction between dairy operations and suppliers, enabling rapid resolution of issues and proactive quality management. Suppliers receive immediate feedback on quality parameters, enabling them to make adjustments that improve milk quality and increase their earnings.

Performance benchmarking helps identify top suppliers and provides recognition for excellence while offering improvement guidance for underperforming operations. This collaborative approach builds a network of high-quality suppliers that provides competitive advantages in raw material sourcing.

Transform Your Dairy Business Today

The dairy industry’s future belongs to operations that embrace technology to drive efficiency, ensure quality, and maximize profitability. Milk collection software provides the foundation for this transformation, delivering measurable improvements in operational efficiency, quality control, and financial performance.

The investment in modern milk collection software pays for itself through reduced operational costs, improved quality premiums, and enhanced regulatory compliance. More importantly, it positions your dairy business for sustainable growth in an increasingly competitive marketplace.

Don’t let outdated processes hold back your dairy operation’s potential. Experience firsthand how milk collection software can revolutionize your business operations and drive unprecedented growth.

Ready to transform your dairy operations? Schedule your personalized demo today and discover how milk collection software can boost your profitability while streamlining every aspect of your business.