How is milk distributed: The Economics of Milk Collection

Running a successful dairy operation in today’s competitive market requires more than just quality milk production. For dairy industry owners and cooperative managers, the economics of milk collection represents one of the most significant operational challenges – and opportunities – in the entire supply chain. Every day, millions of gallons of milk must be collected from farms across vast geographic areas, transported under strict temperature controls, and delivered to processing facilities within narrow time windows.

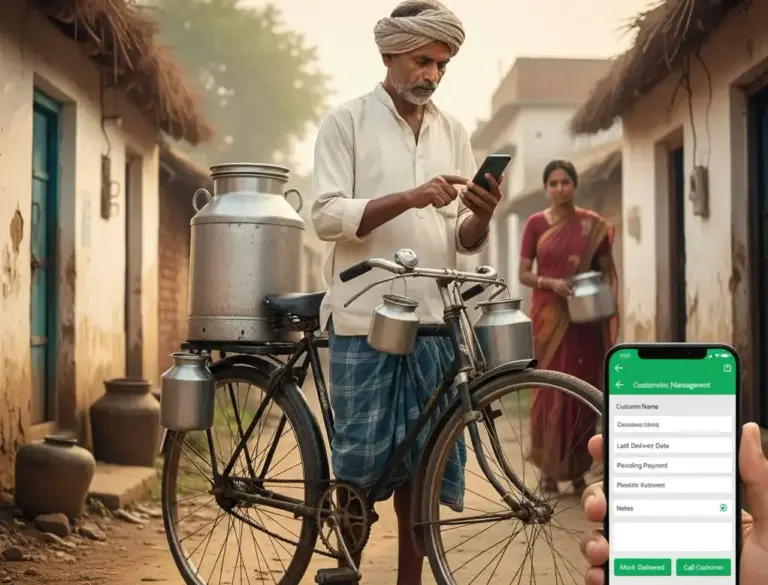

The traditional approach to milk collection often relies on fixed routes, manual scheduling, and decades-old logistics practices that fail to adapt to changing conditions. However, forward-thinking dairy businesses are discovering that intelligent fleet management systems can transform their operations, dramatically reducing costs while improving service quality and farmer satisfaction.

Understanding the True Cost of Milk Collection

Before diving into solutions, it’s essential to understand the full scope of collection costs that impact your bottom line. Transportation typically accounts for 8-12% of total milk procurement costs, but hidden inefficiencies can push this figure much higher.

Fuel costs represent the most visible expense, but they’re just the tip of the iceberg. Vehicle maintenance, driver wages, insurance, and depreciation all contribute to the total cost per mile. More critically, inefficient routing leads to increased wear on vehicles, higher fuel consumption, and extended collection times that can compromise milk quality.

Consider this scenario: A poorly optimized 200-mile collection route that could be completed in 180 miles represents a 11% inefficiency. Multiply this across an entire fleet operating 300 days per year, and the wasted resources quickly compound into six-figure losses.

The ripple effects extend beyond direct costs. Late collections can stress relationships with farmers, potentially leading to contract losses. Temperature excursions during extended routes can result in milk rejection at processing facilities. Driver overtime due to inefficient scheduling increases labor costs and contributes to workforce burnout.

The Power of Route Optimization Algorithms

Modern route optimization technology has evolved far beyond simple distance calculations. Today’s algorithms consider dozens of variables simultaneously to create truly optimized collection schedules that adapt to real-world conditions.

Advanced optimization systems factor in farm pickup volumes, time windows, vehicle capacity constraints, driver schedules, and road conditions. They can dynamically adjust routes based on weather patterns, traffic conditions, and unexpected changes in farm production levels. Most importantly, these systems continuously learn from historical data to improve future routing decisions.

The results speak for themselves. Dairy cooperatives implementing sophisticated route optimization report 15-25% reductions in total mileage, 20-30% decreases in fuel costs, and 10-15% improvements in on-time collection performance. These improvements directly translate to enhanced profitability and improved farmer satisfaction scores.

GPS Tracking: Real-Time Visibility and Control

GPS tracking technology provides dairy managers with unprecedented visibility into their fleet operations. Real-time location data enables proactive management of collection schedules, allowing dispatchers to respond quickly to unexpected delays or route changes.

Beyond basic location tracking, modern GPS systems provide comprehensive fleet analytics. Managers can monitor driver behavior patterns, identify inefficient driving habits, and implement coaching programs that reduce fuel consumption and vehicle wear. Geofencing capabilities automatically notify managers when vehicles deviate from approved routes or spend excessive time at specific locations.

The quality assurance benefits are equally compelling. GPS data provides complete documentation of collection timelines, enabling dairy processors to verify that milk has been handled according to temperature and time requirements. This traceability becomes invaluable during quality audits or in the event of contamination investigations.

Temperature monitoring integration with GPS systems ensures that cold chain requirements are maintained throughout the collection process. Automated alerts notify managers immediately if temperature excursions occur, enabling rapid response to protect milk quality.

Automated Scheduling: Precision at Scale

Manual scheduling processes that rely on spreadsheets and intuition simply cannot compete with automated scheduling systems that process vast amounts of data to optimize collection operations.

Automated scheduling considers farm production patterns, seasonal variations, and historical data to predict optimal pickup frequencies for each location. The system automatically adjusts collection schedules based on tank capacity, milk production trends, and quality requirements. This precision reduces unnecessary trips to farms with low production while ensuring high-volume producers receive appropriate service levels.

Integration with farm management systems enables seamless communication of production data, allowing the scheduling system to make informed decisions about pickup timing and vehicle assignment. Farmers benefit from more predictable collection schedules, while dairy operations achieve better vehicle utilization and reduced operational costs.

How Milk is Distributed Through Modern Collection Networks

Understanding how milk is distributed from farm to processing facility reveals the critical importance of efficient collection systems. Modern milk distributing centers serve as crucial hubs that coordinate the flow of milk from hundreds of farms across wide geographic areas.

The distribution process begins with sophisticated demand forecasting that predicts processing facility requirements. Collection schedules are then optimized to ensure adequate milk supply while minimizing transportation costs. Advanced milk distributing centers employ cross-docking strategies that allow milk from multiple farms to be consolidated for efficient transport to processing facilities.

Real-time communication between collection vehicles, farms, and processing facilities ensures that unexpected changes in production or demand can be quickly accommodated. This flexibility is essential for maintaining the delicate balance between supply and demand in the dairy industry.

Quality Maintenance Throughout the Collection Process

Intelligent fleet management systems play a crucial role in maintaining milk quality from farm to processor. Automated monitoring systems track temperature, agitation levels, and contamination risks throughout the collection process.

Route optimization algorithms prioritize collection sequences that minimize milk storage time on vehicles while ensuring that temperature-sensitive loads are processed quickly. GPS tracking enables rapid response to equipment failures or other issues that could compromise milk quality.

Predictive maintenance capabilities use vehicle performance data to schedule maintenance activities that prevent unexpected breakdowns during collection runs. This proactive approach protects both milk quality and operational efficiency.

Farmer Satisfaction: The Human Element

While technology drives operational efficiency, maintaining strong relationships with dairy farmers remains essential for long-term success. Intelligent fleet management systems actually enhance farmer satisfaction by providing more consistent, reliable service.

Automated notification systems keep farmers informed about collection schedules and any changes that may occur. GPS tracking enables accurate arrival time predictions, allowing farmers to plan their daily activities more effectively. Consistent, on-time collections reduce stress for farm operators and demonstrate the professionalism of the dairy operation.

Performance metrics generated by fleet management systems provide objective data for service quality discussions with farmers. Transparency in collection performance builds trust and strengthens long-term relationships.

Measuring Success: Key Performance Indicators

Successful implementation of intelligent fleet management requires careful monitoring of key performance indicators that demonstrate return on investment. Cost per mile, on-time collection percentage, and fuel efficiency metrics provide immediate feedback on system performance.

Quality indicators such as temperature excursion frequency and milk rejection rates help ensure that cost savings don’t compromise product quality. Farmer satisfaction surveys and contract retention rates measure the long-term health of producer relationships.

Vehicle utilization rates and driver productivity metrics identify opportunities for further optimization and help justify capital investments in fleet expansion or replacement.

Implementation Strategy for Dairy Operations

Successfully implementing intelligent fleet management requires a phased approach that minimizes operational disruption while maximizing benefits. Begin with a comprehensive assessment of current collection operations to identify the greatest opportunities for improvement.

Pilot programs using a subset of routes allow dairy operations to validate system capabilities and refine processes before full-scale deployment. Training programs ensure that dispatchers, drivers, and management personnel can effectively utilize new technologies.

Integration with existing systems requires careful planning to ensure seamless data flow between fleet management platforms and dairy management software. Change management processes help employees adapt to new workflows and embrace technology-driven improvements.

The investment in intelligent fleet management technology typically pays for itself within 18-24 months through reduced operational costs and improved efficiency. Long-term benefits continue to compound as systems learn and adapt to operational patterns.

Future-Proofing Your Dairy Collection Operations

The dairy industry continues to evolve, with increasing emphasis on sustainability, traceability, and operational efficiency. Intelligent fleet management systems provide the foundation for adapting to these changing requirements while maintaining competitive advantages.

Electric vehicle integration capabilities ensure that dairy operations can transition to sustainable transportation options as technology and infrastructure develop. Advanced analytics prepare operations for predictive maintenance and artificial intelligence-driven optimization.

Investment in intelligent fleet management represents more than just cost reduction – it’s a strategic decision that positions dairy operations for long-term success in an increasingly competitive industry.