How Dairy ERP Solutions Allow Supply Chain to Decrease Spoilage

The dairy industry operates on razor-thin margins where every drop counts. With perishable products, complex supply chains, and fluctuating demand patterns, dairy business owners face unique challenges that can make or break profitability. The difference between success and failure often comes down to one critical factor: how effectively you manage your supply chain operations.

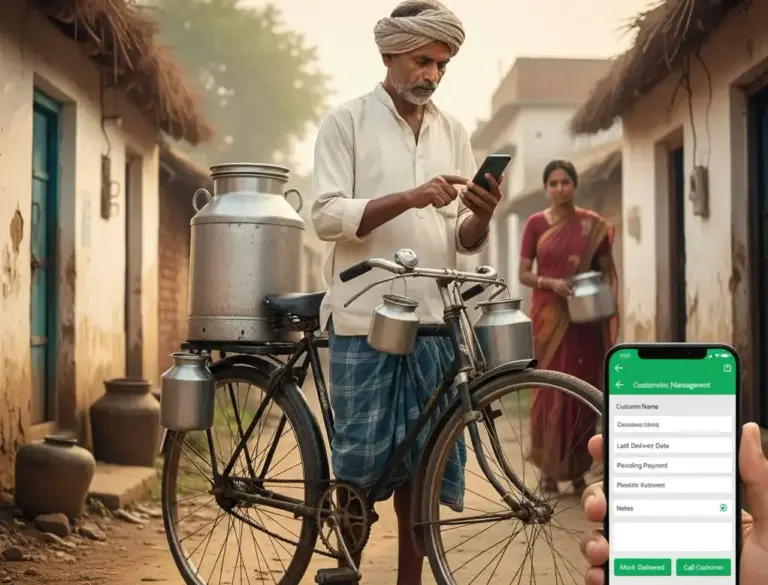

Traditional manual processes and disconnected systems are no longer sufficient in today’s competitive dairy market. Modern dairy ERP solutions have emerged as game-changing tools that transform how dairy businesses manage their operations, from farm to consumer. These comprehensive systems don’t just digitize processes—they revolutionize supply chain management to dramatically reduce spoilage and boost profit margins.

The Hidden Costs of Supply Chain Inefficiency in Dairy Operations

Every dairy business owner understands the pain of product spoilage, but many underestimate its true financial impact. Beyond the obvious loss of inventory value, inefficient supply chain management creates a cascade of hidden costs that erode profitability.

Product spoilage in the dairy industry typically ranges from 5-15% of total production, representing millions of dollars in lost revenue annually for medium to large operations. However, the real cost extends far beyond the wholesale value of spoiled products. When milk or dairy products spoil, businesses lose the entire value chain investment—from feed and labor costs at the production level to processing, packaging, and distribution expenses.

Consider a typical milk distributing center handling 50,000 gallons daily. A modest 3% spoilage rate translates to 1,500 gallons of lost product daily, or approximately $2,250 in direct losses. Multiply this across a year, and you’re looking at over $820,000 in preventable losses—money that could flow directly to your bottom line with proper supply chain optimization.

The ripple effects compound these losses further. Spoiled products require disposal costs, create inventory gaps that disappoint customers, damage brand reputation, and often trigger emergency procurement at premium prices to meet demand. These secondary costs can double or triple the actual financial impact of spoilage.

How Dairy ERP Solutions Transform Supply Chain Management

Modern dairy ERP solutions address these challenges through integrated technology platforms that unify every aspect of supply chain operations. Unlike traditional systems that create data silos, comprehensive ERP solutions provide real-time visibility across the entire operation, from production planning to final delivery.

The transformation begins with complete integration of previously disconnected processes. Production schedules, inventory levels, quality control data, transportation logistics, and customer demand patterns all flow through a single, unified system. This integration eliminates the communication gaps and data delays that contribute to spoilage and inefficiency.

Real-time data visibility becomes a powerful competitive advantage. Instead of relying on yesterday’s reports or gut instincts, dairy business owners can make informed decisions based on current conditions. When a production batch is running behind schedule, the system immediately alerts logistics teams to adjust delivery routes. If quality sensors detect temperature fluctuations in storage, inventory managers receive instant notifications to take corrective action.

Automated workflows replace manual processes that are prone to errors and delays. Purchase orders generate automatically when inventory reaches predetermined levels. Quality control checkpoints trigger alerts if products approach expiration dates. Transportation schedules adjust dynamically based on real-time demand patterns and traffic conditions.

Forecasting Excellence: Predicting Demand to Minimize Waste

Accurate demand forecasting represents one of the most impactful ways dairy ERP solutions reduce spoilage and increase profits. Traditional forecasting methods rely heavily on historical averages and seasonal trends, but modern ERP systems leverage advanced analytics and machine learning algorithms to predict demand with remarkable precision.

These sophisticated forecasting engines analyze multiple data streams simultaneously. Historical sales patterns combine with current market trends, weather forecasts, seasonal variations, promotional activities, and even social media sentiment to generate highly accurate demand predictions. The system learns continuously, refining its predictions based on actual outcomes to improve accuracy over time.

For dairy businesses, this forecasting precision translates directly into reduced spoilage and improved cash flow. Instead of overproducing to avoid stockouts, businesses can produce optimal quantities that match actual demand. A dairy operation that improves forecasting accuracy from 70% to 85% typically sees spoilage rates drop by 20-30%, while simultaneously reducing inventory carrying costs and improving cash flow.

Advanced ERP systems also enable scenario planning and what-if analysis. Business owners can model different production scenarios to understand the financial implications of various decisions. What happens if we increase production by 10% next month? How will a new promotional campaign impact demand patterns? These insights enable proactive decision-making rather than reactive crisis management.

Inventory Management: The Science of Optimal Stock Levels

Effective inventory management in the dairy industry requires balancing multiple competing objectives: minimizing spoilage, avoiding stockouts, optimizing cash flow, and maintaining product quality. Dairy ERP solutions solve this complex optimization problem through intelligent inventory management modules that consider product-specific characteristics and business constraints.

The system tracks not just quantity and location, but also critical quality parameters like production dates, expiration dates, batch information, and storage conditions. Advanced algorithms automatically rotate stock using first-in-first-out (FIFO) principles while considering product-specific shelf life requirements. This ensures older products move through the supply chain before newer inventory, minimizing spoilage losses.

Dynamic safety stock calculations adjust automatically based on demand variability, supplier reliability, and seasonal patterns. Rather than relying on static safety stock levels that may be excessive during stable periods or insufficient during peak demand, the system continuously optimizes inventory levels to maintain service levels while minimizing carrying costs.

Multi-location inventory optimization becomes particularly powerful for dairy businesses operating multiple facilities or distribution centers. The ERP system can automatically balance inventory across locations, moving products from overstocked facilities to those experiencing high demand. This optimization reduces both spoilage at overstocked locations and stockout costs at understocked facilities.

Logistics Optimization: Getting Products to Market Efficiently

Transportation and logistics represent significant cost centers in dairy operations, often accounting for 8-12% of total revenue. Dairy ERP solutions optimize these operations through integrated transportation management modules that consider product perishability, delivery time windows, vehicle capacity constraints, and cost optimization simultaneously.

Route optimization algorithms plan delivery schedules that minimize transportation costs while ensuring product quality. The system considers factors like delivery time windows, vehicle refrigeration requirements, driver availability, and customer priorities to create optimal delivery routes. Real-time traffic and weather data enable dynamic route adjustments to maintain on-time delivery performance.

Temperature monitoring and cold chain management become seamlessly integrated into logistics operations. GPS-enabled temperature sensors provide continuous monitoring throughout transportation, with automatic alerts if conditions fall outside acceptable ranges. This proactive monitoring prevents quality issues and reduces the risk of delivering compromised products to customers.

Load optimization ensures maximum vehicle utilization while respecting weight limits and product compatibility requirements. The system automatically groups compatible products and optimizes loading sequences to minimize handling time and reduce the risk of product damage during transportation.

Financial Impact: Quantifying ROI from Supply Chain Optimization

The financial benefits of implementing comprehensive dairy ERP solutions extend across multiple areas of operations, creating compounding returns on investment that typically justify implementation costs within 12-18 months.

Direct spoilage reduction represents the most visible financial benefit. Dairy operations implementing advanced ERP systems typically see spoilage rates decrease by 25-40% within the first year. For a medium-sized dairy operation with $50 million in annual revenue, this translates to $625,000-$1,000,000 in prevented losses annually.

Inventory carrying cost reduction provides additional financial benefits. Optimized inventory levels typically reduce working capital requirements by 15-25%, freeing up cash for other business investments or debt reduction. Lower inventory levels also reduce storage costs, insurance expenses, and the risk of obsolete inventory write-offs.

Labor productivity improvements create ongoing operational savings. Automated processes reduce manual data entry, eliminate duplicate work, and enable employees to focus on higher-value activities. Most dairy operations see administrative labor costs decrease by 20-30% while improving data accuracy and process reliability.

Transportation cost optimization delivers immediate bottom-line impact. Optimized routing and load planning typically reduce transportation costs by 10-15%, while improved on-time delivery performance enhances customer satisfaction and retention.

Getting Started: Implementation Considerations for Dairy Business Owners

Implementing dairy ERP solutions requires careful planning and consideration of business-specific requirements. Successful implementations focus on selecting systems specifically designed for dairy operations rather than generic ERP platforms that may not address industry-specific needs.

Key selection criteria should include native support for dairy-specific processes like batch tracking, shelf life management, and regulatory compliance reporting. The system should handle multiple units of measure (gallons, pounds, cases) and complex pricing structures common in dairy operations. Integration capabilities with existing systems like accounting software, production equipment, and customer portals ensure seamless data flow across the organization.

Change management represents a critical success factor in ERP implementations. Employee training, process documentation, and clear communication about benefits help ensure user adoption and maximize system value. Most successful implementations include dedicated project teams and phased rollouts that minimize disruption to daily operations.

Data migration and system integration require careful attention to ensure accuracy and completeness. Historical data, customer information, vendor records, and inventory balances must transfer accurately to maintain business continuity. Professional implementation services typically prove invaluable in ensuring smooth transitions and optimal system configuration.

The Competitive Advantage of Modern Dairy Operations

Dairy businesses implementing comprehensive ERP solutions gain significant competitive advantages that extend beyond cost savings and spoilage reduction. Real-time visibility into operations enables faster response to market changes and customer needs. Data-driven decision making replaces intuition-based management, leading to more consistent and profitable outcomes.

Customer service improvements result from better inventory visibility, accurate delivery commitments, and proactive communication about potential issues. When customers can rely on consistent product availability and on-time delivery, loyalty and retention improve significantly.

Regulatory compliance becomes more manageable through automated documentation and reporting capabilities. The system maintains complete traceability records, simplifies audit processes, and ensures adherence to food safety regulations without additional administrative overhead.

Scalability advantages enable business growth without proportional increases in administrative complexity. As dairy operations expand into new markets or add product lines, the ERP system provides the operational foundation to support growth efficiently.

The dairy industry continues evolving rapidly, with increasing consumer demands for quality, sustainability, and transparency. Dairy ERP solutions provide the technological foundation necessary to meet these evolving expectations while maintaining profitability and operational efficiency.

Ready to transform your dairy operation’s supply chain management and unlock significant cost savings? Discover how our comprehensive dairy ERP solution can reduce spoilage, optimize operations, and increase profits for your business. Schedule a personalized demo today to see the potential impact on your bottom line.